Performance Results

Demonstrating exceptional accuracy and reliability across diverse testing conditions.

Understanding the Metrics

R² Score (0.9836)

What it means: The model explains 98.36% of the variance in MAF values. This is exceptional - scores above 0.9 are considered excellent in machine learning.

Why it's good: Nearly perfect correlation between predictions and actual values, indicating the neural network has learned the underlying patterns effectively.

RMSE (2.9638)

What it means: On average, predictions are off by ±2.96 units from the true MAF value. This represents the typical prediction error.

Why it's excellent: For MAF sensors (typically measuring 0-500+ g/s), an error of ~3 units represents less than 1% deviation - highly precise for real-world applications.

MSE (8.7843)

What it means: The average of squared prediction errors. Penalizes larger errors more heavily than smaller ones.

Why it's good: Low MSE indicates consistent accuracy with few large prediction errors - critical for engine optimization where precision matters.

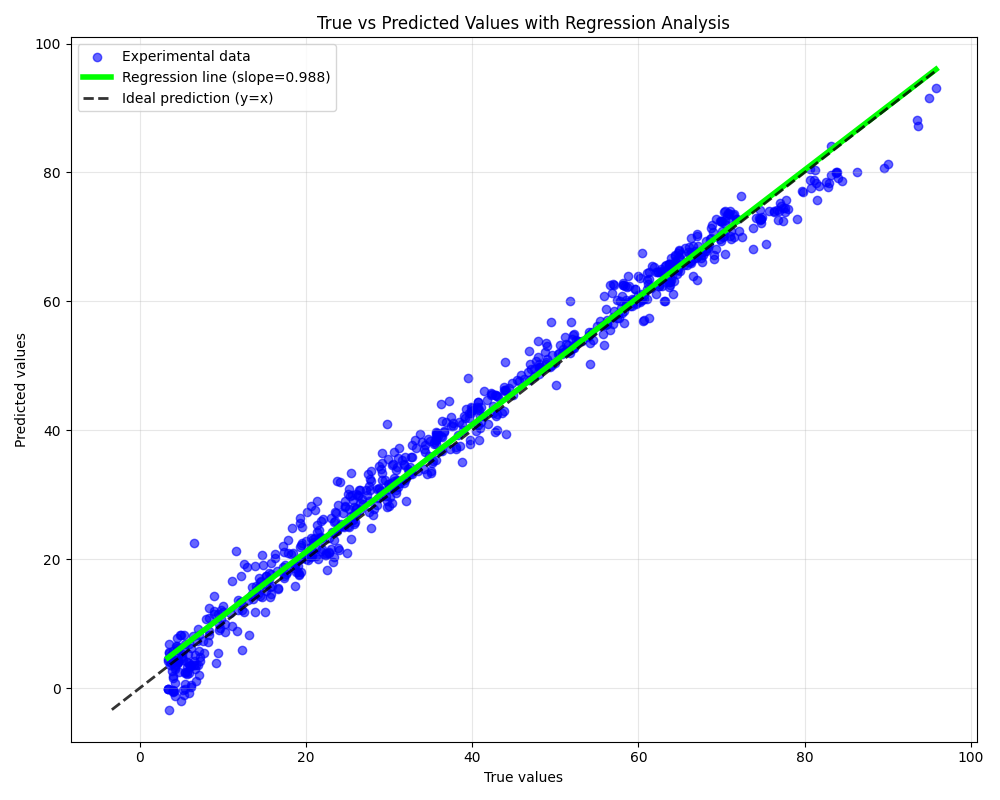

Visual Performance Analysis

MAF Prediction vs Actual Values

Neural network predictions (blue) vs actual MAF values with regression line and ideal prediction line for comparison