Cooling Optimization Study

This project explores a simple fin design for an insulated pipe that delivers oil 1°C too hot.

Group

Tue-4-2

Members

Dominique Taylor

Cameron Barton

Ever Muniz

Date

August 26 2025 - September 16 2025

Problem Statement & Objectives

Engineering challenge analysis and optimization requirements for the Frantoio Franci olive oil facility.

The Challenge

The Frantoio Franci has an olive oil processing facility that requires a cost-effective solution to reduce their hot olive oil temperature by 1°C leading up to the bottling process. The current system lacks sufficient heat dissipation capacity, creating a bottleneck in production efficiency.

Current Operating Conditions

Constraints & Requirements

Cost Optimization

Minimize material and installation costs while achieving temperature reduction

Space Limitations

Fin must be installed above existing insulation with 6-inch clearance

Performance Target

Achieve exactly 1°C temperature reduction through enhanced convection

Material Selection

Evaluate aluminum and copper options with different surface treatments

Material Optimization

Determine the most cost-effective fin material and required length to achieve the target 1°C temperature reduction through systematic experimental analysis.

Success Criteria

- • Achieve 1°C temperature reduction

- • Minimize total project cost

- • Validate theoretical predictions

Experimental Validation

Validate theoretical heat transfer calculations through controlled laboratory experiments and compare predicted versus actual fin performance. Determine the ability of each fin material through testing. Experimental data will lead to theoretical application providing a solid basis for cost-benefit analysis.

Validation Methods

- • Temperature profile measurements

- • Heat transfer rate calculations

- • Fin/cost efficiency analysis

Design Recommendation

Provide quality engineering recommendations for fin material and dimensions based on comprehensive cost-benefit analysis.

Deliverables

- • Optimal material selection

- • Required fin dimensions

- • Implementation cost analysis

Approach to the Problem

Theoretical framework and methods used to address the heat dissipation challenge.

Theoretical Framework

Heat Transfer Equation

q = h·A·(T₂-T₁) + σ·e·A·(T₂⁴-T₁⁴)

Heat Dissipation Required

q = ṁ·cₚ·ΔT

Energy Balance

h·A·ΔT+σ·e·A·(T₂⁴-T₁⁴) = ṁ·cₚ·ΔT

Common Legend

Material Selection Strategy

1. Determining Materials to Use

We picked 2 commonly used and easily accessible materials for heat dissipation fins: copper and aluminum. After which we decided to paint an extra copper fin black to evaluate the effect it would have on radiation of heat. This gave us 3 fins to evaluate and compare: Aluminum, Pure Copper , Pure Copper painted.

2. Evaluating Performance

Performance evaluation included:

- Measure temperature dissipation and emissivity for each material

- Calculate the heat transfer coefficient of each material

- Determining temperature profiles along each test fin (6"x1")

- Assess the length and cost it would take to cool the oil

3. Comparing Materials

Using a cost-benefit analysis, we compared the performance of each material and also calculated the length that would be required. We then determined the fin material that would be most cost-effective and practical for cooling the oil.

Fin Material Properties

| Material | Thermal Conductivity (W/m·K) | Emissivity (ε) | Cost ($/ft) | Heat Transfer Coefficient (W/m²·K) |

|---|---|---|---|---|

| Pure Copper (bright) | 395 | 0.66 | $7.70 | 5 |

| Pure Copper (black paint) | 395 | 0.98 | $7.90 | 20 |

| 6061 Aluminum (bright) | 240 | 0.7 | $1.10 | 10 |

Experimental Procedures and tools

Systematic methodology for testing fin materials and validating heat transfer performance.

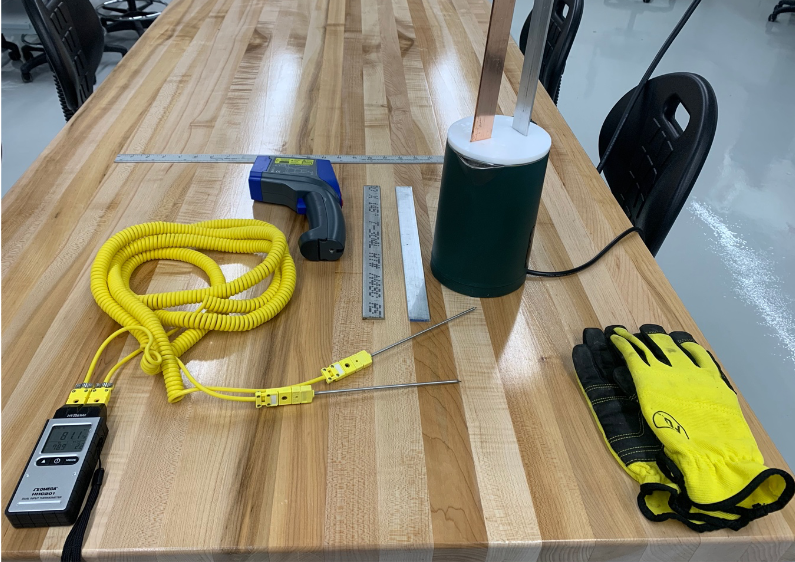

Laboratory Setup & Equipment

Laboratory setup showing the fin testing apparatus with temperature measurement points

Tools & Equipment Needed

Heat Source System

- Kettle for boiling water

- Controlled electric heater (90°C ± 0.1°C)

- Insulated lid to simulate how the fins will be mounted

Measurement Instruments

- Type-K thermocouples (yellow) with closed and exposed beads

- Digital thermocouple readout device

- Glass thermometer (for calibration)

- Infrared temperature sensor (determine emissivity)

Safety & Additional Tools used outside of this experiment

- Heat-resistant gloves

- Thermal paste for interface contact

- Cutting and finishing tools for fin preparation

- Black matte paint and application equipment

- Safety equipment (eyewear, lab coats)

Test Materials

The following materials were prepared as standard 6"x1" test fins for comparative analysis:

Pure Copper (Bright)

Pure Copper (Black Paint)

6061 Aluminum (Bright)

Step-by-Step Experimental Protocol

Preparation & Equipment Setup

- Equipment Verification: Ensure all required equipment is present and functional. If any items are missing, contact the Lab manager or assistant.

- Assembly: Assemble the equipment according to the diagram and verify full functionality of all components before proceeding.

Initial Setup & Calibration

-

Heat Source Preparation:

Heat water in the electric kettle to approximately 90°C, then turn it OFF.

Safety Note: Do not place the exposed junction thermocouple in water when the electric kettle is powered on, as it is not grounded.

- Thermocouple Calibration: Verify the accuracy of all thermocouples using the glass thermometer as a reference standard.

Experimental Setup

- Fin Selection & Mounting: Select the desired test fins (Copper, Black-Painted Copper, or Aluminum) and insert them securely into the Teflon block.

-

System Activation:

Position the fins and the block properly, then reactivate the electric kettle.

Caution: The kettle features an automatic shutoff when water reaches boiling point. Exercise caution when handling hot equipment.

Measurement & Data Collection

- Temperature Profile Measurement: Measure and record the temperature at both the fin base and tip. Also record the ambient room temperature.

- Steady State Monitoring: Continue monitoring until temperatures stabilize and the system reaches steady state (no significant temperature changes over time).

- Final Data Recording: Carefully document all final temperature readings for later analysis.

- Emissivity Determination: Use the infrared thermometer to measure the emissivity of the fin. This is possible because you know the actual fin temperature from your thermocouple readings.

Experimental Process Flow

Equipment Setup

Assemble and verify all equipment

Calibration

Verify accuracy of measuring instruments

Testing

Run experiment until steady state

Data Collection

Record temperatures and emissivity values

Data & Results

Experimental measurements and analysis outcomes for the fin optimization study.

Experimental Trials

Temperatures (base T₁ and tip T₂) were recorded every minute for 10 minutes for each fin. Values shown are the averaged time-series across four trials per material (Room temperature held at 23°C).

Pure Copper (Bright) - Temperature Over Time (Averaged)

| Time (min) | Base Temp (T₁) °C | Tip Temp (T₂) °C | Room Temp (T∞) °C | ΔT (T₁ - T₂) °C |

|---|---|---|---|---|

| 0 | 23.70 | 23.70 | 23.00 | 0.00 |

| 1 | 38.13 | 26.65 | 23.00 | 11.48 |

| 2 | 42.48 | 32.88 | 23.00 | 9.60 |

| 3 | 49.85 | 38.90 | 23.00 | 10.95 |

| 4 | 51.58 | 42.38 | 23.00 | 9.20 |

| 5 | 52.68 | 44.68 | 23.00 | 8.00 |

| 6 | 52.95 | 46.33 | 23.00 | 6.62 |

| 7 | 50.80 | 45.15 | 23.00 | 5.65 |

| 8 | 52.63 | 47.78 | 23.00 | 4.85 |

| 9 | 52.70 | 48.93 | 23.00 | 3.77 |

| 10 | 53.58 | 49.00 | 23.00 | 4.58 |

Temperature Data Plots

Base Temperature (T₁) Measurements

Fig 1. Base temperature measurements across all trials

Tip Temperature (T₂) Measurements

Fig 2. Tip temperature measurements across all trials

Heat Dissipation Analysis

Measured Heat Dissipation (6"x1" Fin)

Heat dissipation calculated using q = h·A·(T₂-T₁) + σ·e·A·(T₂⁴-T₁⁴)

Required Heat Dissipation

Required dissipation calculated from q = ṁ·cₚ·ΔT where cₚ = 2000 J/kg·K

Scaling Analysis

To achieve the required heat dissipation of 500 W, we must scale up from our 6"x1" test fins to determine the optimal fin length for each material type:

| Material | Test Fin Dissipation | Required Length | Total Cost |

|---|---|---|---|

| Copper (Bright) | 4.57 W | 109.59 in (9.13 ft) | $70.32 |

| Copper (Black) | 10.30 W | 48.5 in (4.04 ft) | $31.93 |

| 6061 Aluminum | 5.88 W | 85 in (7.08 ft) | $7.80 |

Optimal Fin Length Analysis

Pure Copper (bright)

Required length for 1°C reduction

6061 Aluminum (bright)

Required length for 1°C reduction

Pure Copper (black)

Required length for 1°C reduction

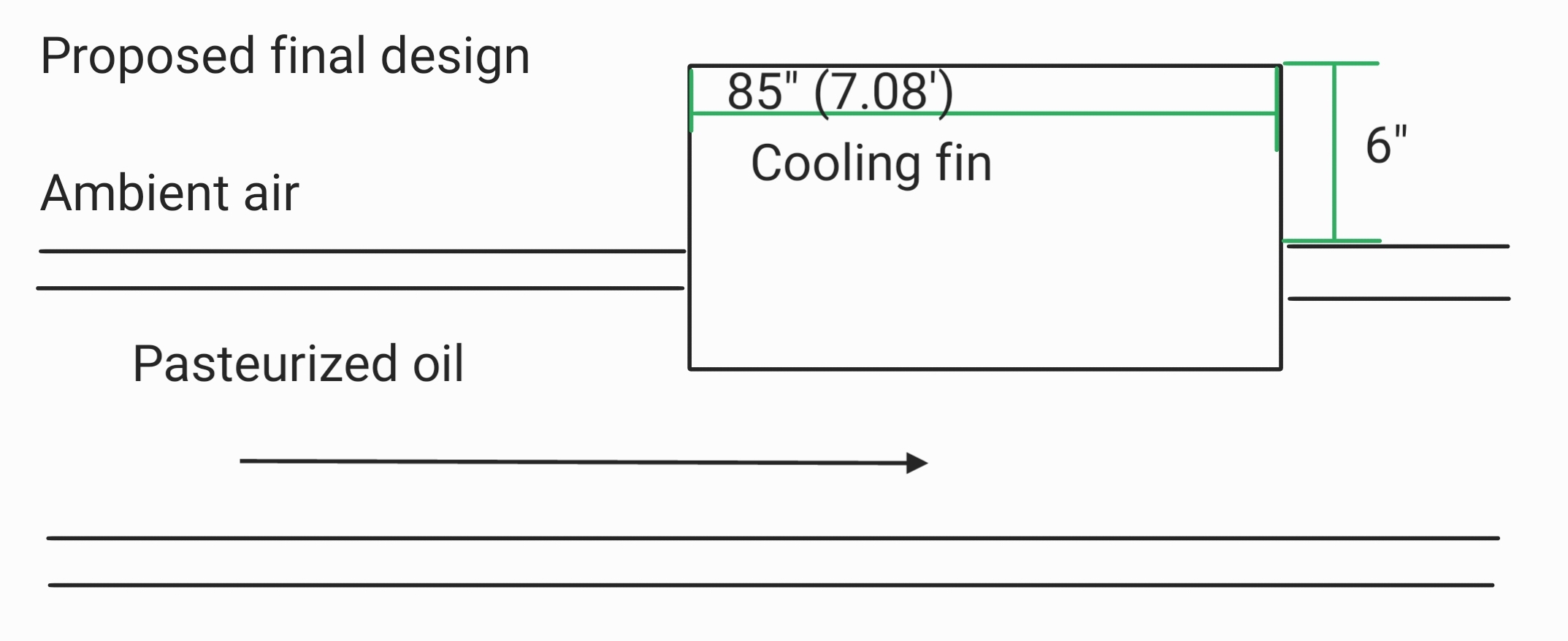

Conclusions & Recommendations

Engineering assessment and recommendations for optimal fin implementation.

Discussion

Through experimental data collected, we determined the emissivity and convective heat transfer coefficients for each material. After determining these necessary material properties, we created a simulation to determine the optimal fin length required to reduce the temperature of the pasteurized oil by 1 °C for each material, by calculating energy balances using heat transfer laws. After determining the length required for each fin, we determined the cost of materials for each respective fin. The aluminum fin was significantly cheaper compared to both the bright and dark copper fins. Although the dark copper fin would only need to be 48.5” long compared to the 85” long aluminum fin, the total cost of materials was still significantly lower for the aluminum fin ($7.80 compared to $31.93).

Potential sources of error in this experiment include uncertainties in temperature measurements. Inaccuracies may arise from thermocouple placement, such as inconsistent contact with the fin surface or interference from steam rising out of electric kettle, which could raise the recorded fin temperature. Additionally, the water bath was maintained around 90 C, however the temperature gradually dropped over time, requiring the kettle to be reheated. This fluctuation in water temperature may have led to variations in the boundary conditions across trials.

Conclusion Statement

At Frantoio Franci's request, we were tasked with optimizing a cost-effective and heat-dissipating fin to reduce the hot olive oil temperature by 1 °C, leading up to the bottling process. Based on our team's experimental work, we recommend the optimal fin length and material to be a 6061-aluminum fin having dimensions 6" tall x 0.125" thick x 85" long.

Recommended Fin Design

Optimal Aluminum Fin Configuration

Fig 3: Recommended 6061 aluminum fin design for optimal heat dissipation

Design Specifications

Key Dimensions

Installation Considerations

Cost Analysis

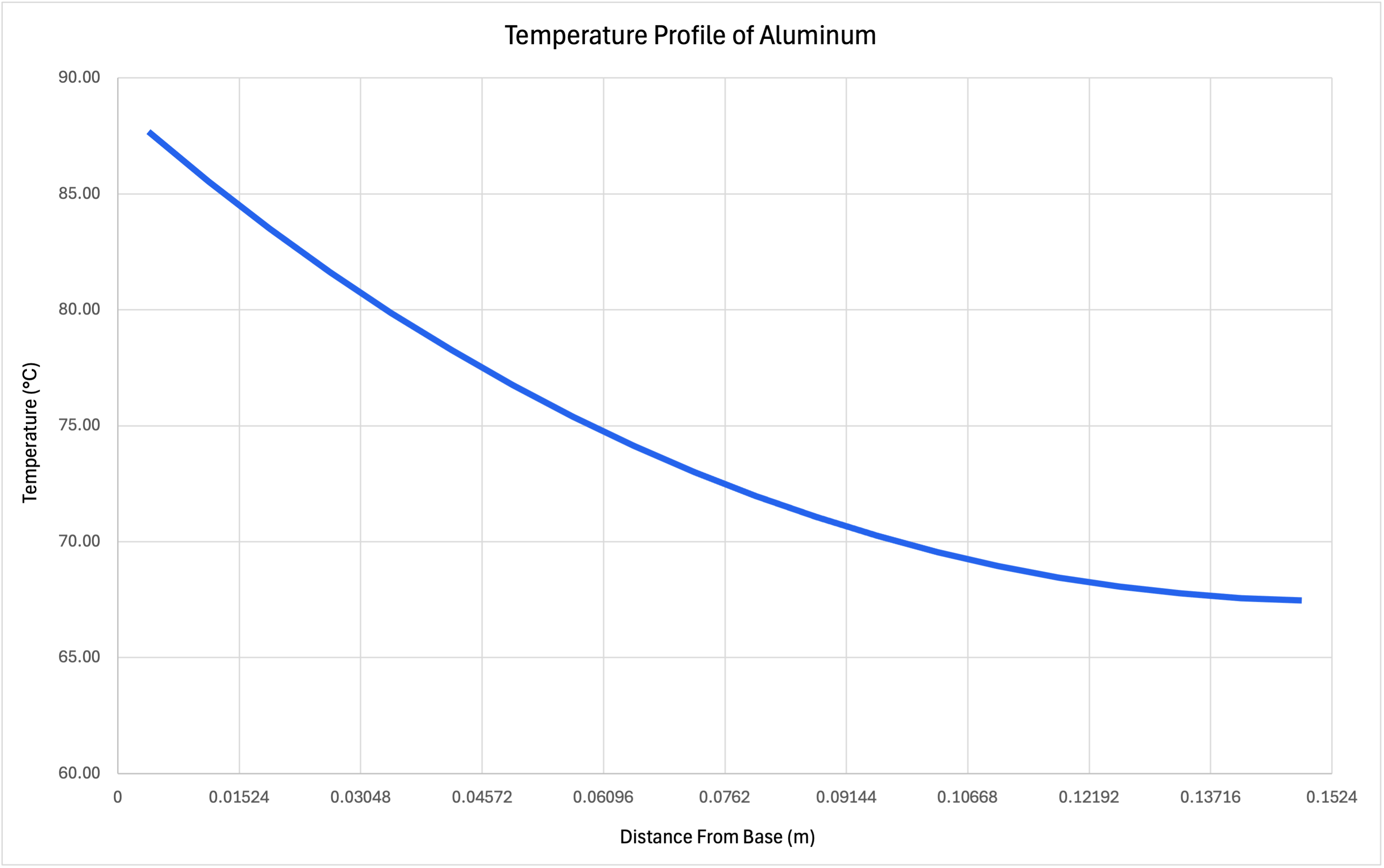

Aluminum Fin Temperature Profile

Predicted Temperature Distribution

Fig 4: Predicted temperature distribution along the aluminum fin length

Fin Performance Parameters

Base Temperature

90.0°C

Tip Temperature

42.2°C

Heat Transfer Rate

500 W

Fin Length

85"(7.08')

Temperature Model

The temperature distribution follows an exponential decay pattern from base to tip, with effective heat transfer to the ambient environment (23°C). The fin provides uniform cooling across its length, maintaining efficient thermal gradient without hotspots.

AI Development Disclaimer

Note: AI tools were used solely in the development of interactive features and fine styling of this project webpage. All experimental data collection, analysis, calculations, and engineering conclusions presented in this heat transfer study were conducted independently without AI assistance.